Swedish electro-mobility startup Stilride is introducing 3D printing capabilities with the aim of having an automated production process by the end of this year.

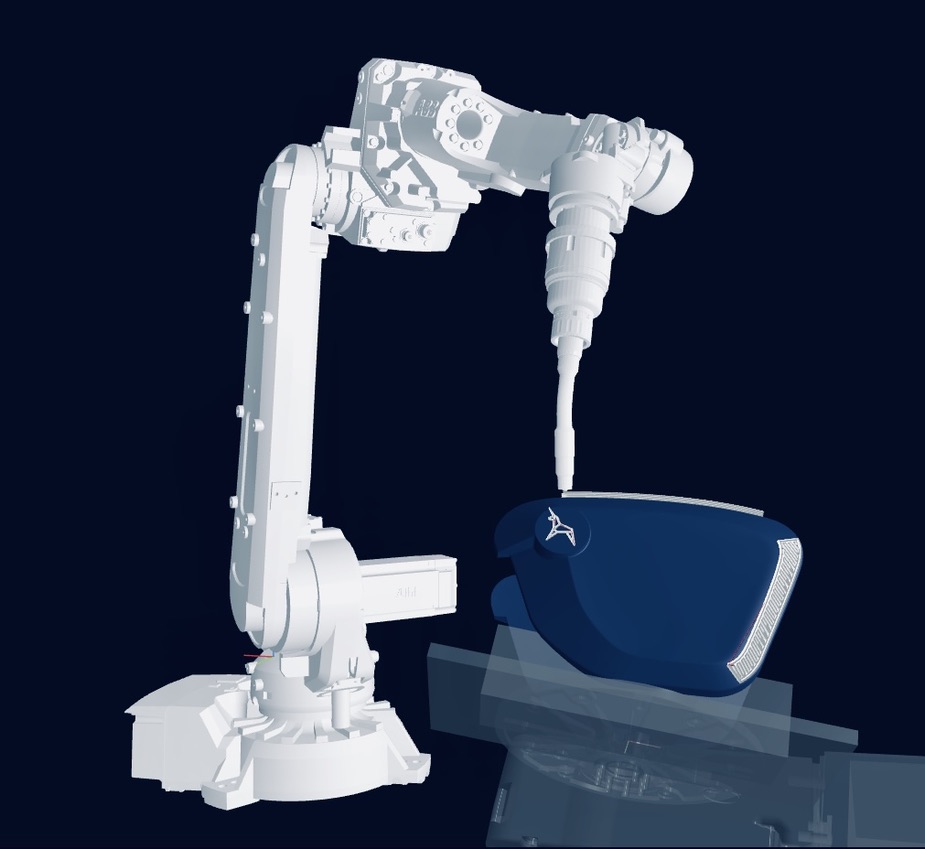

By entering into a partnership with Swedish robotics company Adaxis, Stilride will be able to produce complex components out of steel using additive manufacturing. Until now, components such as hinges, fenders and side covers had to be sourced from external suppliers.

The technology will simplify the production process for Stilride’s first e-motorbike Sport Utility Scooter One (SUS1) substantially, bringing additional robot-powered manufacturing capabilities in-house and further improving the material efficiency of each bike.

Jonas Nyvang, CEO and Co-Founder at Stilride, told Zag Daily: “Our goal is to have an automated production process in action by the end of 2023. We are setting up our first micro-factory in Stockholm this Spring.

“This will accelerate our journey to automation by enabling us to test and develop our processes on a bigger scale on-site until the technology meets our rigorous standards for effective and sustainable manufacturing.”

Adaxis’ software allows engineers to programme a robotic arm to 3D print large and complex steel, plastic, composite and concrete parts quickly, whilst significantly reducing costs and material waste.

“We’ll also be able to make parts to order, meaning we can be extremely agile when it comes to customising each motorbike according to customer preferences and producing bespoke units,” said Nyvang.

Adaxis’s commercial standard speed is 5 kg/h for metal and up to 30 kg/h for composite, but it depends on the application.

Industrial origami

The technology will add to Stilride’s plan to rewrite the design rules for electro-mobility with a new manufacturing technique dubbed ‘industrial origami’.

The firm’s patented ‘Stilfold’ technique involves the use of robotic arms to fold steel over curves using minimal materials to build e-mobility products that are lighter, greener and more sustainable.

Eventually Stilride wants to make its tech suite available to designers and manufacturers who wish to licence it to build their own work.

Besides the SUS1, ‘Stilfold’ is currently being used by Polestar to develop the world’s first climate neutral car and by Swedish space innovation agency I.S.A.A.C to explore how curve folding could be used for construction in outer space.

Emil Johansson, CEO and Co-Founder of Adaxis, said: “Using robotization, we can push the limits of what can be manufactured using 3D technology both in terms of size and shape. Our goal is to speed up the manufacturing process and make it more intuitive, even when it comes to really complex projects, so that everyone can benefit from this technology.”