Batteries are one of the biggest environmental pain points in the micromobility industry. This is because they have a finite lifespan meaning they don’t renew themselves once being harvested or mined and can only be used once. So no matter what kind of battery you use, it will eventually be fully consumed.

Compounding this issue is the growing demand for batteries worldwide. A study by Deloitte projects that 130 million e-bikes will join our roads between 2020 and 2023, which means we will need to make 130 million batteries too (or in some cases more). To put this into context, only 12 million automobiles and trucks are expected to sell across the globe in 2025. Likewise, the micromobility industry as a whole is expected to quadruple by 2030. At some point down the line then, the programmed obsolescence of these batteries is going to become a massive problem.

The issue is not that these lithium-ion batteries cannot be repaired, but that the process to do so is too complex, time-consuming and dangerous.

So whenever a battery does reach the end of its “first” life, companies will often either recycle or repurpose it for “second life” usage in less-stressful applications such as stationary storage.

This would be a logical next step had a study in 2019 – which looked at hundreds of end-of-life batteries – not found that 80 per cent of the cells that made up these batteries were still in working order. Note, a standard battery typically contains between 40 to 60 cells.

Generally, batteries are not suitable for EV use when the delivered capacity or power of a cell is less than 80 per cent of its original rated value, according to the United States Advanced Battery Consortium (USABC).

By examining the entire battery pack, the researchers found that only a small number of the cells failed to hold the required capacity, so to abandon the entire battery pack represents an incomplete usage. The is how the idea of remanufacturing came about, which is replacing defective cells to extend a battery pack’s “first life”.

After the Co-Founder of Gouach, Alexandre Vallette, read a study about micromobility batteries being dumped, he set out to prove that an alternative type of battery could be more eco-friendly.

“It’s like when you look at your remote control for your TV, you don’t throw away the remote control when the batteries stop working,” says Vallette.

Has Gouach found a solution?

Reverting back to why it is difficult to remanufacture a battery pack is because standard batteries are typically soldered together by a battery specialist. And there are quite a few wires wrapped up in them as well.

But French e-mobility battery maker Gouach thinks it has found the answer.

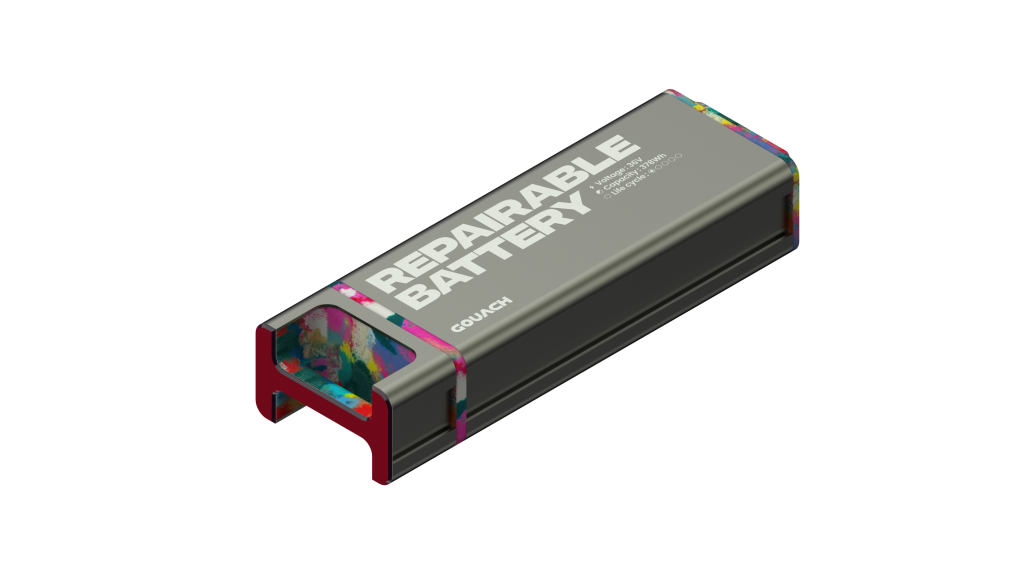

The Bordeaux-based firm’s solution has been to manufacture a solderless, wireless battery specifically for e-bikes, e-scooters and other small EVs.

It is modular meaning each cell can be dismantled and replaced if issues arise, thereby extending the batteries lifetime.

In fact with Gouach’s battery design, Vallette claims they can repair a pack in under ten minutes.

In a product demonstration, CEO and Doctor of Physics Alexandre Vallette, told ZAG Daily: “We have designed it so that the electronic part of the battery can be removed very easily. And then thanks to our kind of compression mechanism, you can just unscrew the battery and gain access to each cell, so you can replace exactly the one or two cells that are the problem instead of throwing out the whole battery.”

To help prove the solution works, Gouach has added connectivity to its batteries so that data can be fed through to an app to tell you about the battery’s lifecycle.

When consultancy firm Magelan put Gouach’s product to the test, they discovered it emitted 2.6 times less CO2 than conventional batteries and consumed 2.5 times less water.

Investors are now catching on, with Gouach announcing last month that it has raised €3 million to scale its patented repairable batteries.

“Gouach is the first European company to tackle the problem of battery obsolescence in the micro-mobility sector in-depth,” says Maximilien Bacot, Managing Partner of the VC fund Breega that led the funding round.

Gouach partners with micromobility operator Dott

Dott became interested in working with Gouach when it caught wind of the possible carbon savings.

“That’s one of the main reasons we started working together,” says Laura Hensel, Dott’s Sustainability Manager.

“This fits our current way of looking at emissions, which is reducing them instead of offsetting them.”

The partnership was officially announced in January this year.

“So what has been achieved between the two of us so far is we’ve been implementing our repairable technology in their casing to see if it technically works. And it seems to be fine, we passed most of the tests. There are a few little things to modify but basically it works. So now we have to find the right way to collaborate together,” says Vallette.

One possibility is for Gouach to run its business like a battery-as-a-service where it rents its batteries to Dott so that Gouach becomes responsible for the life of the battery. These batteries then power Dott’s e-scooter and e-bike fleets, and when one needs repairing, it is sent back to Gouach.

Currently, on average, after 500 cycles or charges, the battery will lose between 20 to 30 per cent of its initial capacity meaning you are able to store less energy, according to Vallette. It is at this point when the pack has lived its full “first life” that it can then be recycled or repurposed.

But Vallette explains that there are caveats to this.

“It depends on many factors like temperature [of the battery], the way you charge them, if you charge them fast or not. So there are many parameters.”

Dott is also looking for end of life solutions for its existing batteries and so another possible way to collaborate is if Gouach can reuse the cells in these packs to make new ones.

Do you think that you will pass on your words of wisdom to Dott’s ground team so that they can swap out the cells themselves?

“This is the kind of question we have been trying to answer, but for the moment we don’t think it’s a good idea because there is also a question of liability. Lithium-ion cells should be handled by somebody who knows exactly what they are doing. So this is why we were thinking of integrating the whole process inside Gouach so that we are then responsible for the batteries.”

By working with Dott, Vallette hopes to set new standards for the small battery industry. One which dumps the current obsolescent business model and not the battery itself.